-

Ostravská 350/2b

Opava 9, 747 70

-

Call us

553 780 331

-

Write to us

info@mvb.cz

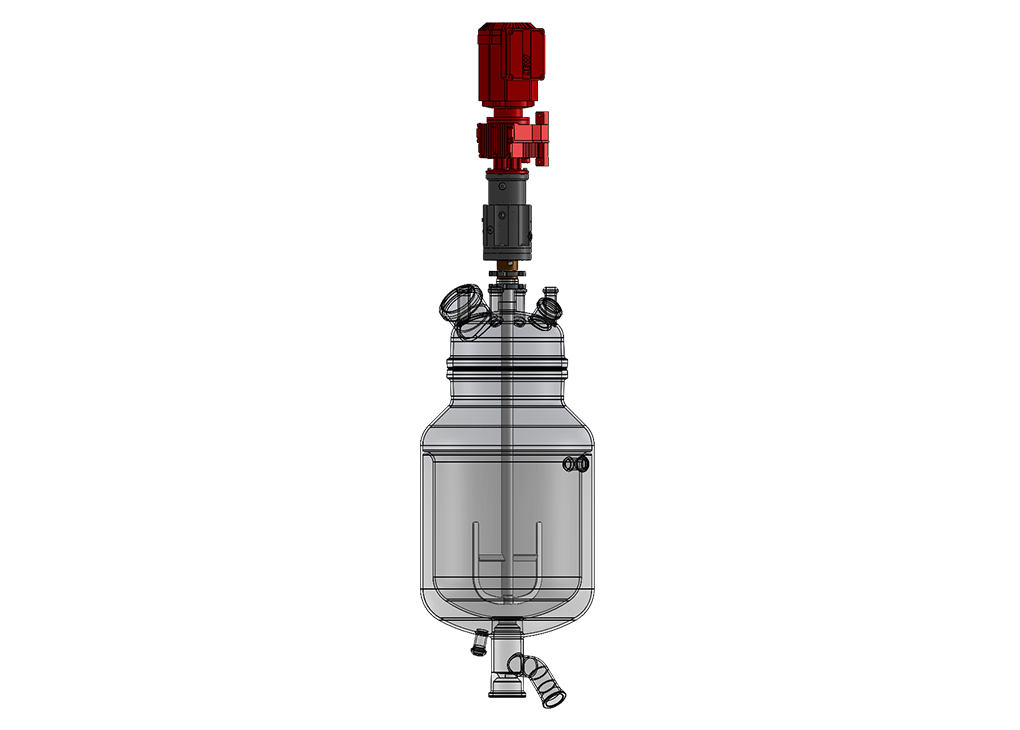

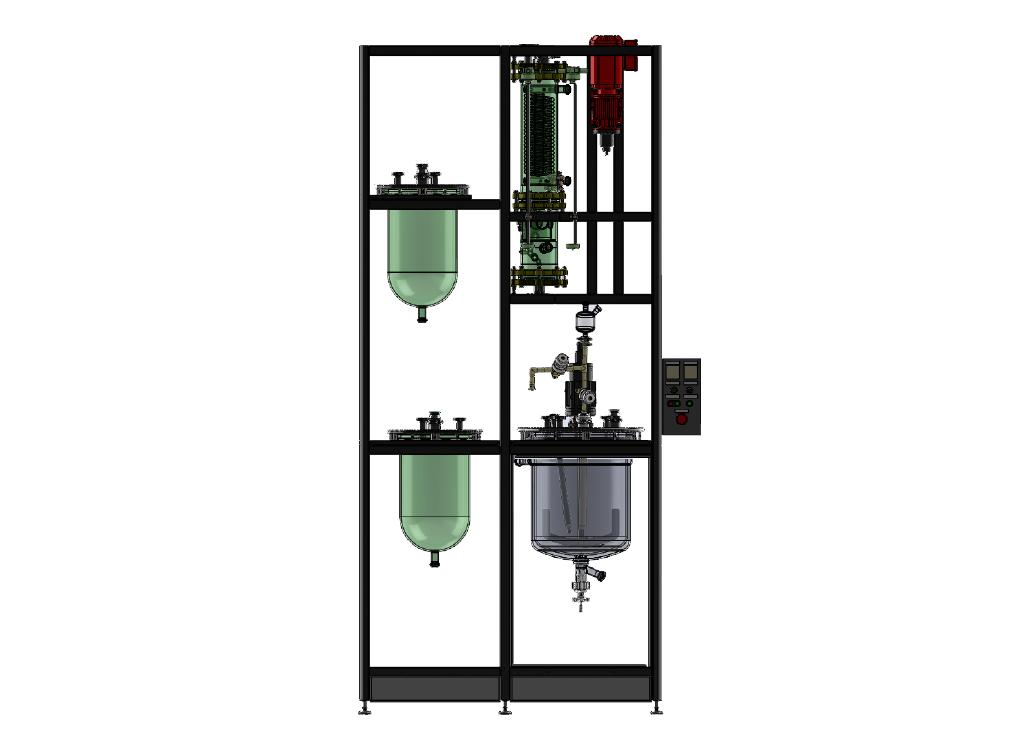

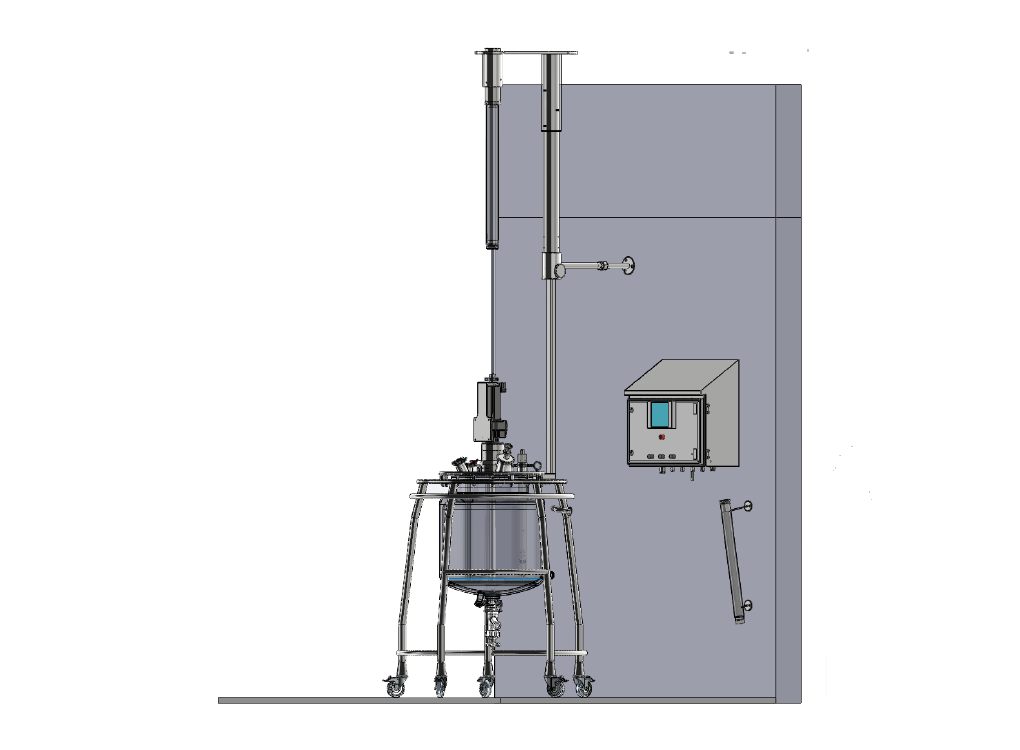

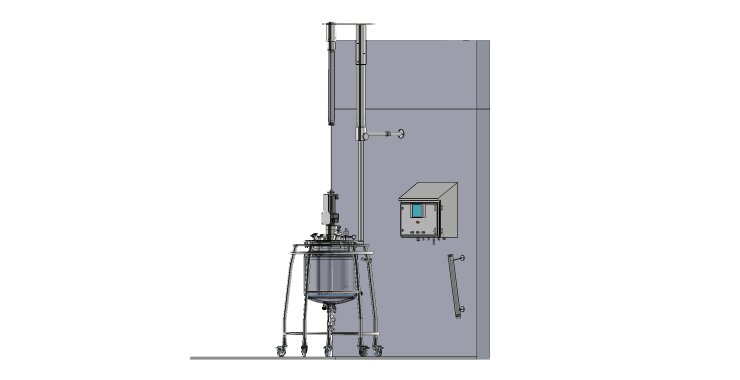

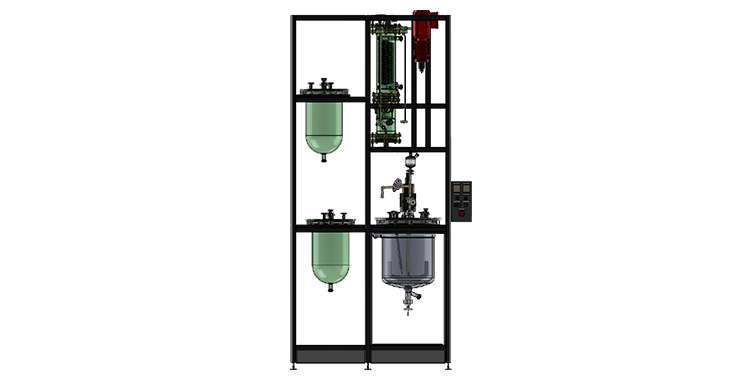

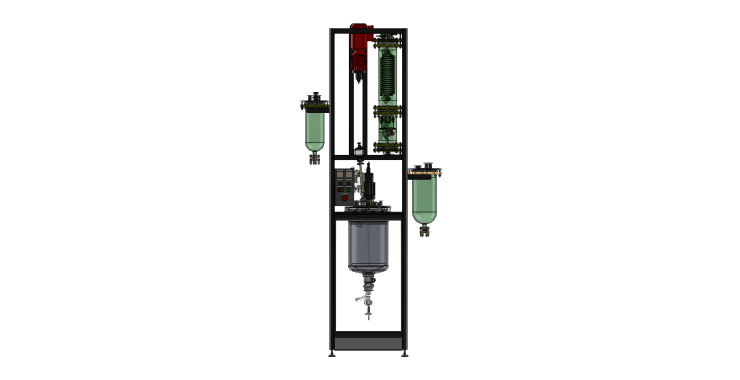

We design stirred reactors for demanding operating conditions according to the particular specifications with an emphasis on chemical, pressure and temperature load. We deliver the reactor vessels in a duplicator or a triplicator version with a bottom plug. The reactor can be fitted with various types of stirrers, motors and bearing housings. The reactor contains technological equipment according to the chemical process for which it is intended, control and display elements and recording of values measured over the time. Parts exposed the stirred medium are certified according to EN 10204 2.2, 3.1, (EU) Nr.10/2011, FDA and USP. The equipment complies with regulations resulting from the internationally established "GMP" (good manufacturing practice) rules.

The reactors and the equipment can be used in normal environment or environment with a risk of explosion.

• capacity: 5 to 100 l (triplicator to the maximum of 60 l)

• bottom drain outlet: DN15 to DN50 (drain socket with a bottom plug or drain valve)

Glass lid:

- standard or custom manufacture

Stainless steel lid:

- a choice of implementations, qualities, roughnesses of surfaces and process connections

Coated lid:

- ECTFE, ETFE, PFA (optional conductive implementation for ECTFE and ETFE)

Plastic lid:

- PP, PE, PVDF, PTFE (optional conductive implementation)

VKK-A TYPE for normal environment and environment with a risk of explosion (FTZÚ 13 ATEX 0101 certificate) :

- VKK-A-01 (for most applications; mechanical gland; high chemical resistance; temperature range of the stirred medium: -20 to +180°C)

- VKK-A-10 (in this model, the bearing housing is tempered; designed for the most demanding applications; mechanical gland; high chemical resistance; temperature range of the stirred medium: -80 to +200°C)

VKK-B TYPE:

- designed for simple applications with direct installation on the lid of the stirred tank with integrated front gear motor. It is separated from the medium by a shaft with polished ceramic surface and a special shaft seal. VKK-B is not designed for use in areas with a risk of explosion.

VKK-C TYPE:

- designed for stirring tanks to the capacity of 15 l. For various types of mechanical glands. Easy installation on the lid of the equipment. VKK-C is not designed for use in areas with a risk of explosion.

VKK-X TYPE :

- custom manufacture offering special bearings and a mechanical gland. The bearing housing design corresponds to the location of the equipment (e.g. clean rooms), operating conditions and other requirements (washing and sterilising of the entire equipment).

Stainless steel:

- design and manufacture according to the particular application; various qualities and roughnesses of surfaces

Coated:

- ECTFE, ETFE, PFA (optional conductive implementation for ECTFE and ETFE)

Combined structure:

- special implementation with inner carrier and compensator; PTFE-FDA or PTFE+25% C-FDA are in contact with the stirred medium (double seal system PTFE+FFKM)

• front gear motor (0.15 to 1.5 kW)

• front synchronous servo gear motor

• air motor with epicyclic gear (stainless steel)

• tubular structure with a support plate

• modular system with glazing profiles

• sanitary implementation