-

Ostravská 350/2b

Opava 9, 747 70

-

Call us

553 780 331

-

Write to us

info@mvb.cz

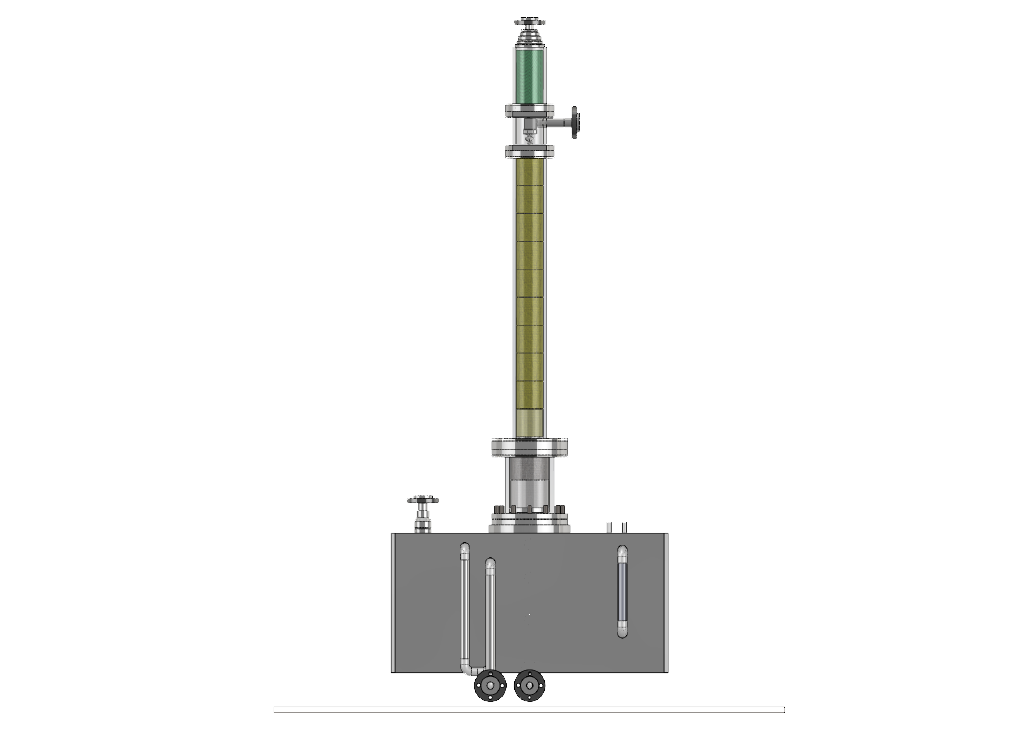

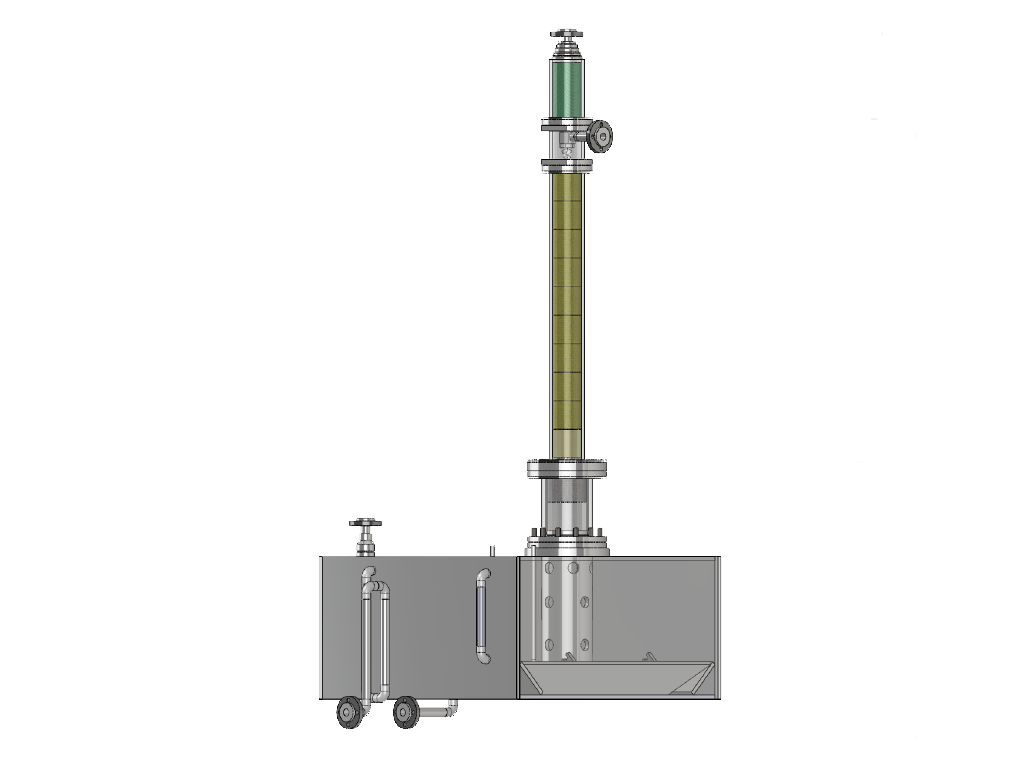

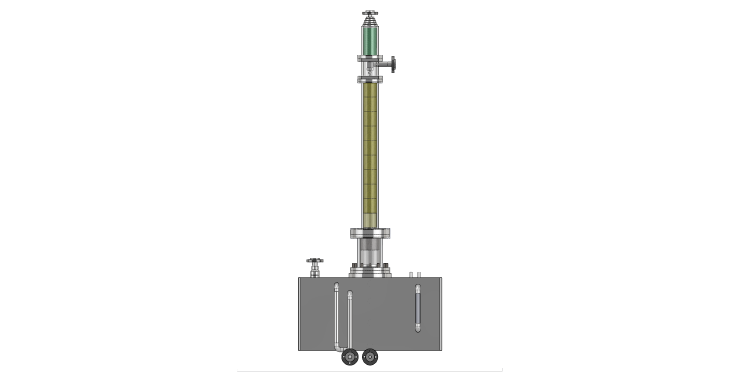

The equipment can be divided into several units, which create the individual weldments. In the design, we put great emphasis on long-term reliability of these devices.

• the dimensions are optimized according to the specifications (input pollution and layout restrictions)

• optional cooling exchanger integrated in the storage tank

• in contact with the medium and air mass: all-plastic construction (conductive/non-conductive) or stainless steel according to the particular specification

A complete set in pneumatic implementation without the necessity of electrical power supply.

- pneumatic control panel (START/STOP, visualization of operation, regulation of the pump, etc.)

- evaluation of limit values with link to the locking conditions of the pump and visualization

From simple equipment to an autonomous system with integrated logic of all operating statuses.

- control panel with basic control or touchscreen panel with an indication of the procedural statuses

- measurement of the level (limit, continuous), flow, pH, conductivity, density, a pressure of the liquid on the discharge and pressure of the air mass (in case of a difference)

- control system for keeping constant operating conditions (pressure of the circulating liquid, adjustable underpressure on the inlet to the absorber)

- a diaphragm pump (standard with active pulse damper or high-speed)

- pump with a magnetic clutch in various materials

- highly chemically resistant vertical impeller pump V-P02-Ex

- impeller pump without rotating parts with a levitating impeller

- radial fans with high chemical resistance

- for normal environment and environment with a risk of explosion

- various types of special shaft seals (defined tightness to the outside environment)

- poured plastic (injected, 3D print of the particles with optimization of parameters)

- oriented filler (porous borosilicic glass 3.3, ceramic, stainless steel)