-

Ostravská 350/2b

Opava 9, 747 70

-

Call us

553 780 331

-

Write to us

info@mvb.cz

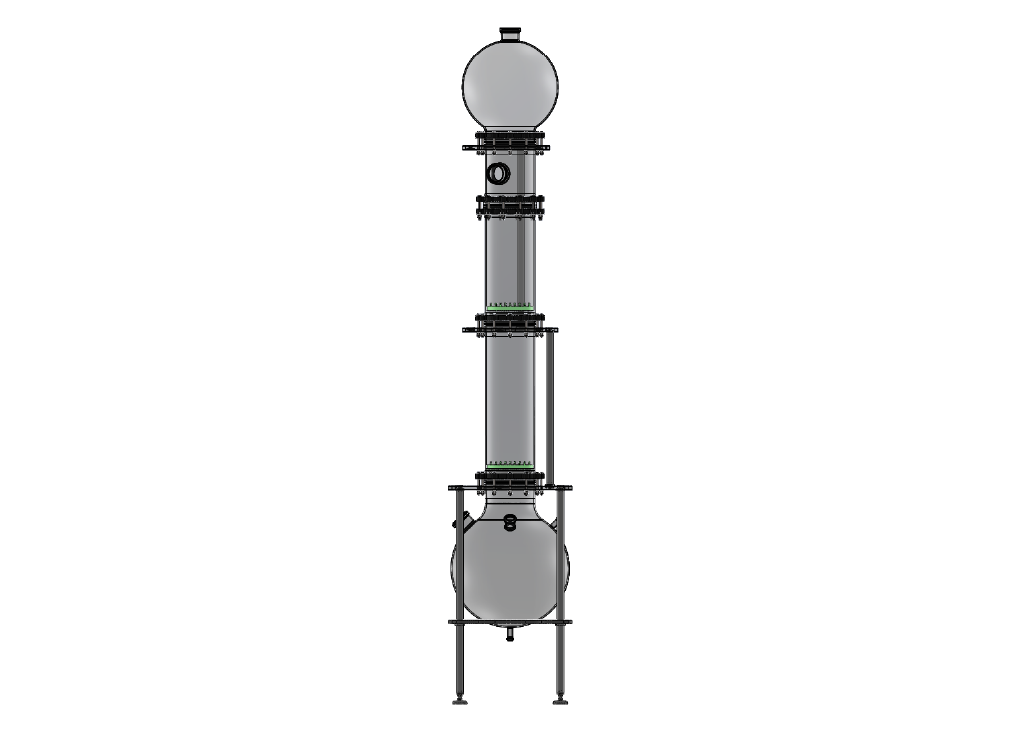

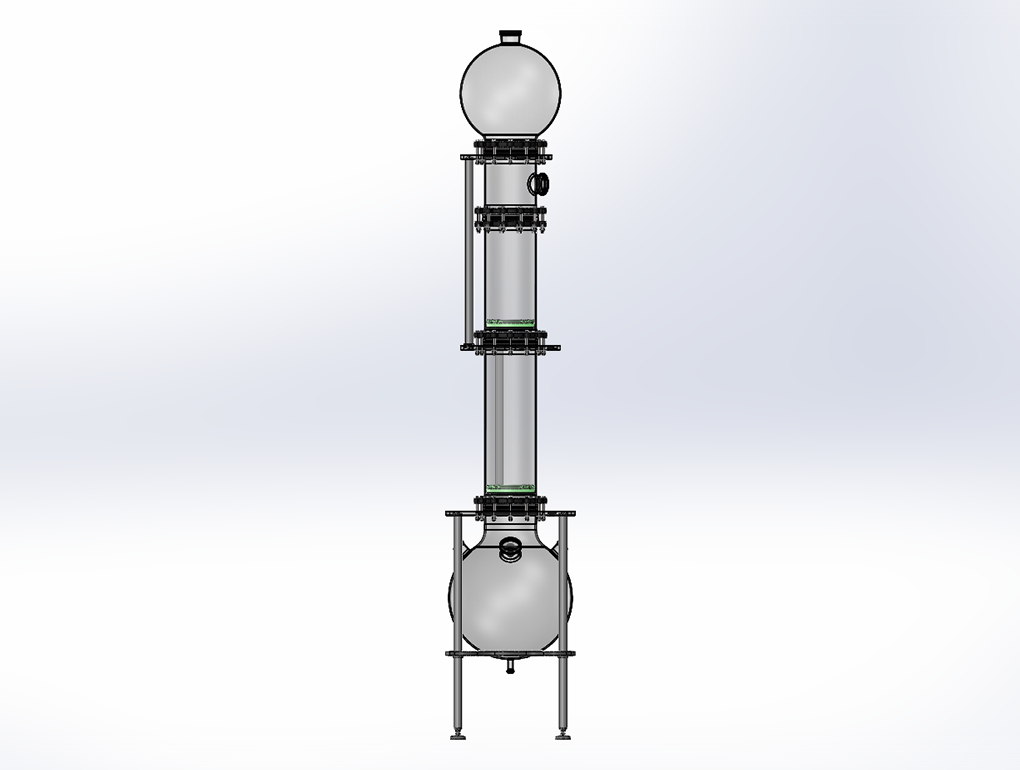

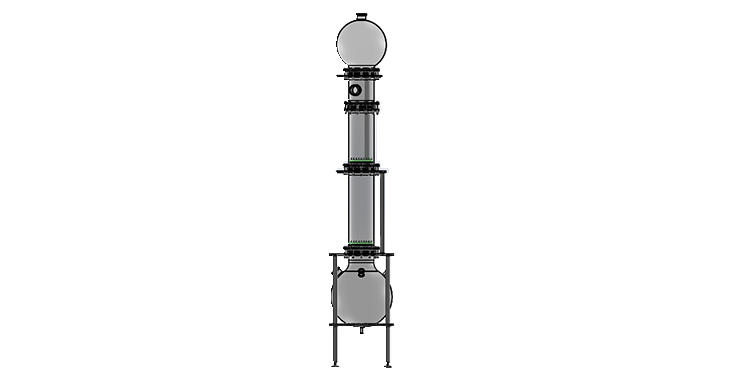

A system assembled from glass components by flange connections. The individual components are housed in the support structure by means of support panels and frames.

• diameter of the column working section: DN50 to DN600 mm

• capacity the scrubbing liquid vessel: 300 l (the restriction applies for the glass)

• in contact with the medium and air mass: borosilicic glass 3.3 and PTFE

A complete set in pneumatic implementation without the necessity of electrical power supply.

• pneumatic control panel (START/STOP, visualization of operation, regulation of the pump, etc.)

• evaluation of limit values with link to the locking conditions of the pump and visualization

From simple equipment to an autonomous system with integrated logics of all operating statuses.

• control panel with basic control or touchscreen panel with indication of the procedural statuses

• measurement of the level (limit, continuous), flow, pH, conductivity, density, pressure of the liquid on the discharge and pressure of the air mass (in case of a difference)

• control system for keeping constant operating conditions (pressure of the circulating liquid, adjustable underpressure on the inlet to the absorber)

• a diaphragm pump (standard with active pulse damper or high-speed)

• pump with a magnetic clutch in various materials

• highly chemically resistant vertical impeller pump V-P02-Ex

• impeller pump without rotating parts with a levitating impeller

• radial fans with high chemical resistance

• for normal environment and environment with a risk of explosion

• various types of special shaft seals (defined tightness to the outside environment)

• poured glass or ceramic filler (Raschig rings, ceramic elements)

• oriented filler (porous borosilicic glass 3.3, ceramic)