-

Ostravská 350/2b

Opava 9, 747 70

-

Call us

553 780 331

-

Write to us

info@mvb.cz

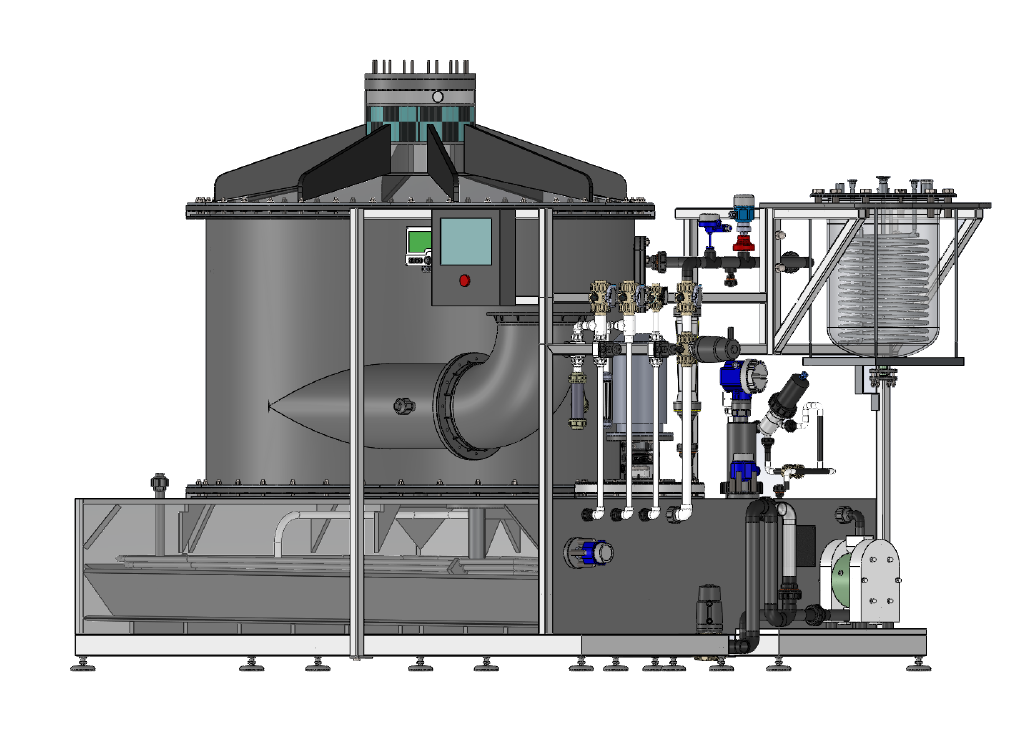

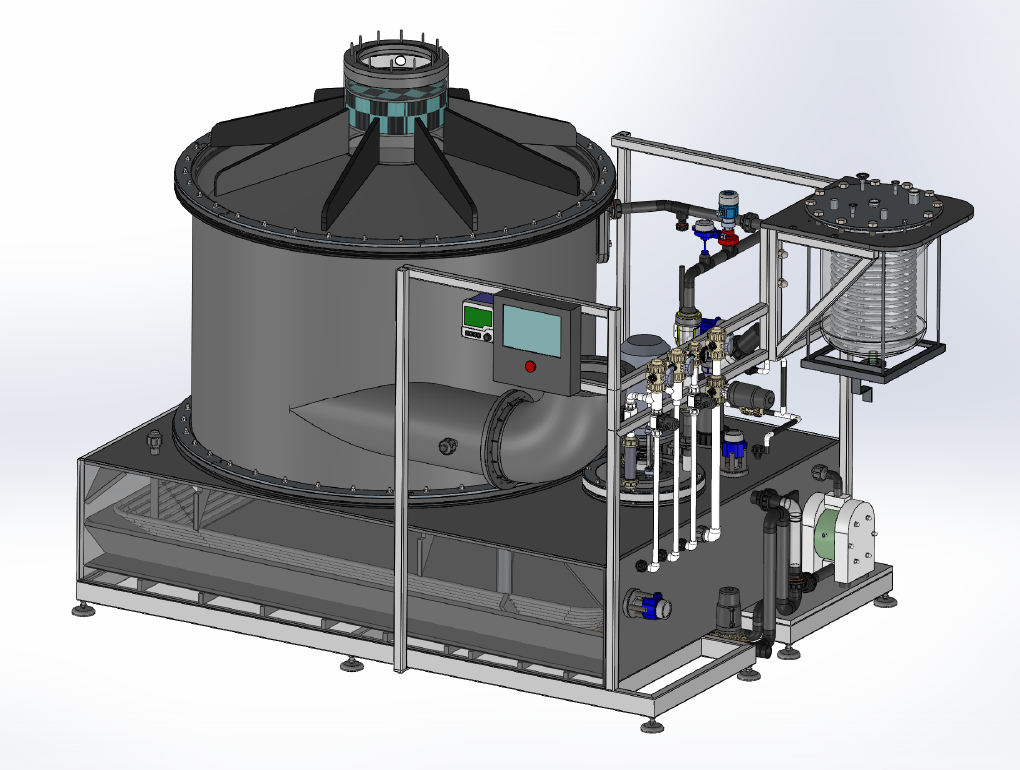

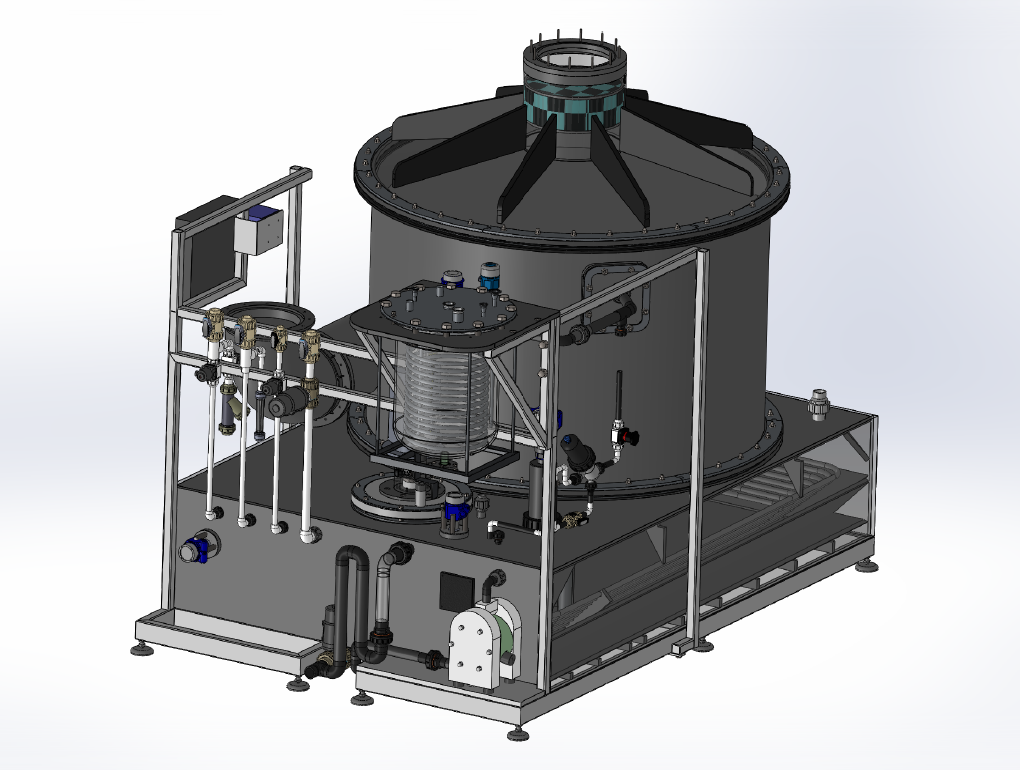

Gas Scrubber (scrubber of waste gases)

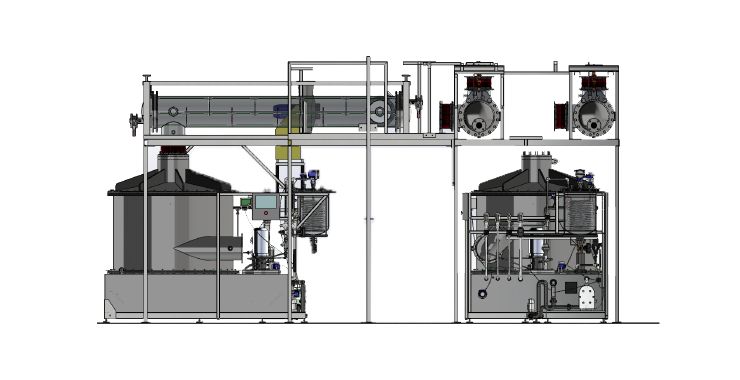

The main purpose of the gas scrubber is to remove inorganic gaseous substances of acid and alkaline character as well as organic substances. The equipment is also suitable for recycling of gaseous reaction components (e.g. ammonia or volatile amines during amination) directly in the manufacture or as a recycling element on the outlet and for reduction of the VOC (volatile organic compounds). The pollutants are removed more efficiently at lower temperatures of the scrubbing agent because the balance of the whole system is governed the Henry's law.

Benefits:

- Gas scrubbers are devices with simple design and high efficiency of separation

- They excel in low maintenance and operation demands

- Gas scrubbers are used in many branches of industry

- Suitable for applications where large volumes of gases need to be scrubbed

- Gas scrubbers are characterized by low loss of pressure and low hydraulic resistance

- Sensitivity to the pollution is minimal

- The equipment is supplied in a tested condition as a functional unit

- The product is certified for environments with a risk of explosion according to regulation 2014/34/EU (ATEX)

Function:

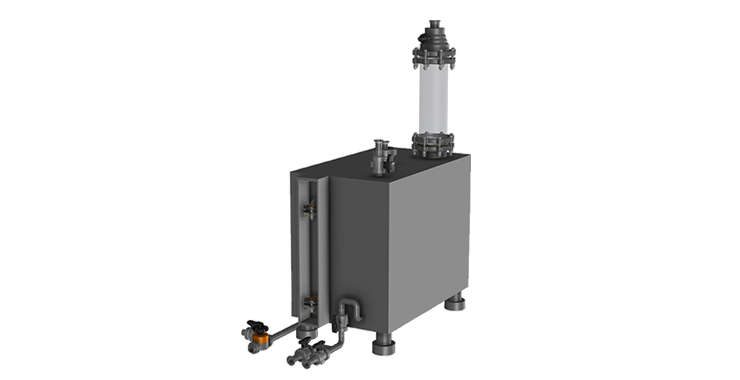

The main part of the sprinkler scrubber is a sprinkler head. It is a vertically oriented cylinder with conical tips on both ends where the pollutants are absorbed during contact of the contaminated gas with the absorbent liquid. The gaseous phase is conducted into the inner space in the bottom section of the sprinkler head in a tangential direction. The liquid phase is conducted to the sprinkler head in the top section of the sprinkler head. The liquid is sprayed by a special spiral nozzle, which produces a spiral liquid film with subsequent atomization into individual drops. The absorption liquid effectively fills the inner space of the sprinkler head where close contact of both phases and a large area of the interfacial boundary are ensured to provide effective transport of the mass between the phases. Drift of the absorbent drops is eliminated by a system of partitions in the top conical section of the scrubber head and by a demister installed on the outlet of the gaseous phase.

The absorbent liquid tank has an integrated heat exchanger for keeping constant working temperature during the scrubbing. The pH is continuously measured during the scrubbing process and the preset pH value is regulated by gradual dosage of agents. The equipment is fitted with a density meter and the water is replenished and changed on the basis of the measured value. Constant pressure on the outlet from the spiral nozzle is maintained by pressure measurement in the circulation circuit with the link to speed control of the circulator pump.

- flow of the air mass: 100 to 2000 m3/h.

- in contact with the liquid medium: high-density polyethylene in conductive implementation, PTFE, FEP, elastomers

- in contact with the air mass: high-density polyethylene in conductive implementation, ePTFE

- acidic scrubbing agent (first level of absorption)

- alkaline scrubbing agent (second level of absorption)

- final fine-scrubbing output agent

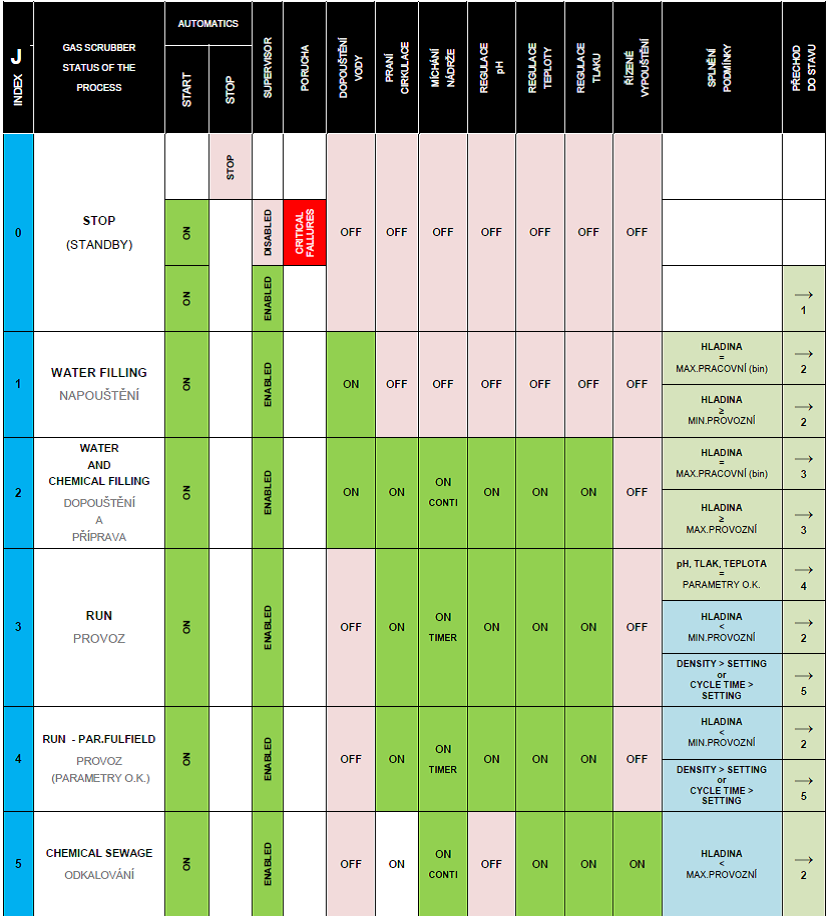

An autonomous system with integrated logics of all operating statuses that follow each other.

0 = STOP

1 = FILLING

2 = REPLENISHING AND PREPARATION

3 = OPERATION in status I.

4 = OPERATION in status II.

5 = SLUDGE REMOVAL

- continuous level measurement in the storage tank

- minimum operational limit level (protection of the pump against dry run)

- maximum operational limit level

- pH measurement (maintaining preset operating value of the scrubbing liquid)

- density measurement (the system automatically evaluates the system according to the preset value and optimizes replenishment of the scrubbing liquid)

- measurement of the circulation circuit pressure (maintains pressure defined on the nozzle and regulates performance of the pump)

- limit sensor of the circulation circuit, the flow, pH, conductivity, density, pressure of the liquid on the discharge and pressure of the air mass (in case of a difference)

- control system for keeping constant operating conditions (pressure of the circulating liquid, adjustable underpressure on the inlet to the absorber)

- diaphragm pump

- pump with a magnetic clutch in various materials

- impeller pump without rotating parts with a levitating impeller

- radial fans with high chemical resistance

- for normal environment and environment with a risk of explosion

- various types of special shaft seals (defined tightness to the outside environment)